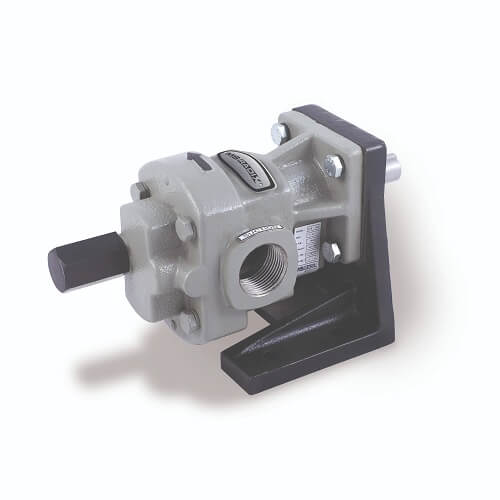

MS Series Rotary Gear Pump

MSRADIX® MS Series Rotary Gear Pumps are self-priming, compact, low noise, efficient, easy maintainable, cost economical for handling viscous and semi-viscous liquids.

MS series pumps are general purpose foot mounted pumps with threaded inlet and outlet ports

-

Size from ½” to 3” BSP.

-

Capacity: 20 LPM to 500 LPM.

-

Maximum working pressure: 10 Bar.

-

Maximum working temperature: 80oC for standard & 200oC for MS (HT).

-

Maximum viscosity: 100000 SSU.

-

Sealing options: oil seal / gland packing / single mechanical seal.

-

Sturdy design and construction to ensure long trouble free life with best performance.

-

Pressure relief valve will be provided in all model.

MS pumps can handle following liquids

-

All kind of mineral oils.

-

All kind of vegetable oils.

-

Coal tar, bitumen, asphalts.

-

Paints and varnish.

-

Sugar molasses & syrups.

-

All kinds of fish and animal oils.

-

Glycerin & glycol.

-

Fuel oil, diesel oil & furnace oil.

-

Soap solution & lard.

-

Glue.

-

Viscous chemicals.

Model & Performance Chart

|

Pump Model |

Suction & Delivery |

Capacity at 1440RPM |

Recommended Motor BHP at Differential Pressure (kg/cm2) with 1500SSU Viscosity |

||||||||||||

|

LPM |

US GPM |

m3/hr |

Kg/cm2 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

||

|

MS-050 |

½” x ½” |

20 |

5.28 |

1.2 |

KW |

0.30 |

0.35 |

0.40 |

0.45 |

0.50 |

0.55 |

0.60 |

0.65 |

0.70 |

0.75 |

|

HP |

0.50 |

0.75 |

1.00 |

||||||||||||

|

MS-075 |

¾” x ¾” |

30 |

7.92 |

1.8 |

KW |

0.37 |

0.45 |

0.54 |

0.62 |

0.69 |

0.77 |

0.85 |

0.92 |

1.01 |

1.09 |

|

HP |

0.75 |

1.00 |

1.50 |

||||||||||||

|

MS-100 |

1” x 1” |

50 |

13.20 |

3.0 |

KW |

0.40 |

0.50 |

0.60 |

0.75 |

0.89 |

1.04 |

1.17 |

1.30 |

1.44 |

1.59 |

|

HP |

1.00 |

1.50 |

2.00 |

||||||||||||

|

MS-125 |

1¼” x 1¼” |

75 |

19.81 |

4.5 |

KW |

0.70 |

1.00 |

1.20 |

1.40 |

1.50 |

1.90 |

1.95 |

2.5 |

2.35 |

2.55 |

|

HP |

1.50 |

2.00 |

3.00 |

||||||||||||

|

MS-150 |

1½” x 1½” |

110 |

29.05 |

6.6 |

KW |

1.05 |

1.45 |

1.95 |

2.10 |

2.40 |

2.65 |

2.95 |

3.25 |

3.60 |

3.75 |

|

HP |

2.00 |

3.00 |

5.00 |

||||||||||||

|

MS-200 |

2” x 2” |

225 |

59.44 |

13.5 |

KW |

2.00 |

2.50 |

3.20 |

3.70 |

4.30 |

4.55 |

5.60 |

6.20 |

6.90 |

7.11 |

|

HP |

3.00 |

5.00 |

7.50 |

||||||||||||

|

MS-250 |

2½” x 2½” |

350 |

92.46 |

21.0 |

KW |

4.15 |

5.20 |

6.10 |

7.30 |

8.20 |

9.10 |

10.30 |

11.20 |

12.10 |

12.25 |

|

HP |

5.00 |

10.00 |

12.50 |

||||||||||||

|

MS-300 |

3” x 3” |

500 |

132.08 |

30.0 |

KW |

4.50 |

6.60 |

8.40 |

9.90 |

11.10 |

12.10 |

13.00 |

13.90 |

14.90 |

15.90 |

|

HP |

10.00 |

15.00 |

20 |

||||||||||||

Material of Construction

| Parts |

MS up to 80oC |

MS (HT) up to 200oC |

| Body |

IS:210 FG 220 C.I. Grade |

IS:210 FG 220 C.I. Grade |

| Back Cover |

IS:210 FG 220 C.I. Grade |

IS:210 FG 220 C.I. Grade |

| Gears |

EN-8 |

EN-363 Nitrided |

| Shaft |

EN-19 H.G. |

EN-19 H.G. |

| Bushes |

Non-Ferrous |

Non-Ferrous |

| Seal |

Neoprene Oil Seal |

Gland Packing |