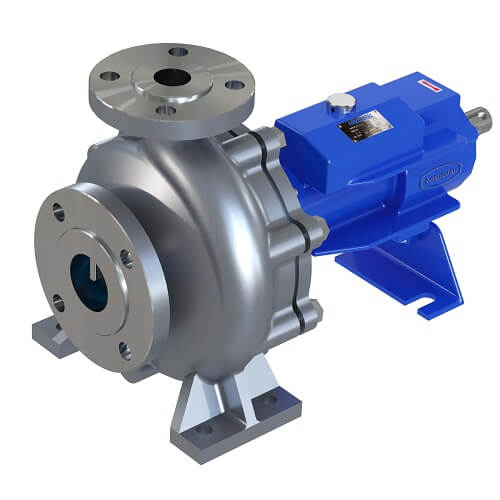

MSMS Series Rotary Gear Pump

MSRADIX® MSMS pumps is all Stainless Steel (SS-316), simple four-piece construction specially designed to handle thinner or thicker & even corrosive liquid having lesser or no lubricating value.

Suction size from ½” to 4”with flange (Class 150 # ASME/ANSI B 16.5).

Capacity: 15LPM to 500 LPM.

Maximum working pressure: 10Bar.

Maximum working temperature: 200oC.

Maximum viscosity: 25000 CST.

Self-lubricating PTFE coated DU bush bearing type pumps for smooth performance in dry condition.

The four-piece construction in the pump makes it easy to clean & maintain and are designed to handle thinner & thicker or even corrosive liquid having less lubricating value.

The pump is provided with double helical nitrided gear to give longer life and also it helps to prevent axial and side thrust.

Sealing options available – gland packing / single mechanical seal / oil seal.

The pump is provided with pressure relief valve.

The pump with jacketing construction is provided to felicitate heating of the pump by steam or thermic fluid.

The pumps direction can be changed clockwise to anticlockwise without opening the pump by changing the position of the relief valve.

Liquids can handle

For firefighting – foam pressuring application.

For machine tools – high pressure coolant transfer.

Heavy viscous liquid transfer application like molasses, magma, soap solution, paints, varnish, vegetable oil, painting ink, spent wash & cosmetic products.

Non-corrosive viscous chemicals.

Application Industries

Oil & gas industry

Steel plant

Paint, varnish & ink industry

Sugar industry

Pharma industry

Chemical industry

Model & Performance Chart

Pump Model (Suction & Delivery)

| Capacity at 1440RPM | Recommended Motor HP at 1440RPM for Pressure | |||||

LPM | US GPM | m3/hr | 0 to 3 kg/cm2 | > 3 to 7 kg/cm2 | > 7 to 10 kg/cm2 | ||

MSMS-50 ½” x ½” | S | 15 | 3.90 | 0.90 | 0.50 | 0.75 | 1.00 |

M | 20 | 5.20 | 1.20 | ||||

MSMS-100 1” x 1” | S | 30 | 7.90 | 1.80 | 1.00 | 1.50 | 2.00 |

M | 35 | 9.20 | 2.10 | ||||

MSMS-150 1½” x 1½” | S | 60 | 15.80 | 3.60 | 1.50 | 2.00 | 3.00 |

M | 75 | 19.80 | 4.50 | ||||

MSMS-200 2” x 2” | S | 100 | 26.40 | 6.00 | 2.00 | 3.00 | 5.00 |

M | 125 | 33.00 | 7.50 | ||||

MSMS-250 2½” x 2½” | S | 150 | 39.60 | 9.00 | 3.00 | 5.00 | 7.50 |

M | 200 | 52.80 | 12.00 | ||||

MSMS-300 3” x 3” | S | 250 | 66.00 | 15.00 | 7.50 | 10.00 | 12.50 |

M | 330 | 87.10 | 19.80 | ||||

MSMS-400 4” x 4” | S | 415 | 109.60 | 24.90 | 12.50 | 15.00 | 20.00 |

M | 500 | 132.00 | 30.00 | ||||

Material of Construction

| Parts | Material |

| Pump Body | CF8M (SS-316) |

| Front Cover | CF8M (SS-316) |

| Back Cover | CF8M (SS-316) |

| Gland Cover | CF8M (SS-316) |

| Rotor / Stator Shaft | AISI (SS-316) |

| Gear | AISI (SS-316) |

| Bushes | Teflon Coated DU |

| Wear Plate | Bronze |

| R.V. Housing | AISI (SS-316) |

| R.V. Piston | AISI (SS-316) |

| R.V. AD Screw | AISI (SS-316) |

| Sealing | Gland Packing / Mechanical Seal |