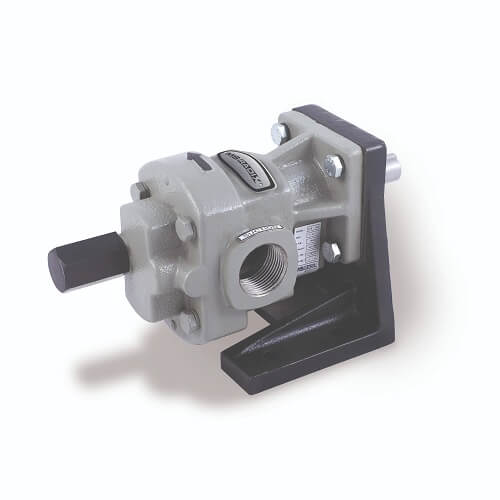

Pl Series Rotary Lobe Pumps

Pl Series Rotary Lobe Pumps

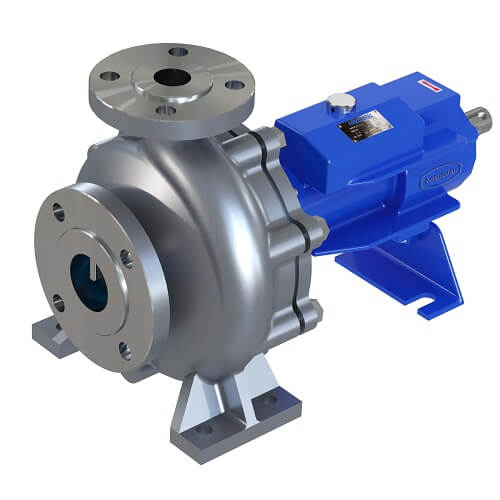

PL series pumps are positive displacement lobe rotor type pumps. As the rotor rotates, the volume in the pump inlet line increases and the fluid is dragged into the pump. The fluid between the rotors and the pump inner wall is conveyed to the pump outlet. The fluid is transferred to the outlet line as a result of the reduction in volume at the outlet with the rotation of the rotor.

PL series pumps are especially designed for easy and quick

assembly & disassembly for cleaning and maintenance. Thanks to its

modular design, all parts of the pump can be changed quickly. The front

surface of the seal is positioned in direct contact with the CIP fluid.

Excellent seal cleanliness ensures a long seal life.

With its unique front-loading seal design, it provides fast

maintenance, easy cleaning and short system downtime. By simply removing

the front cover, the rotors and packing can be removed without leaving

the pump line.

PL series pumps consist of 4 different gearboxes and 2 or 4

different casings in each gearbox. It has 10 different bodies in

total.

PL series pumps are positive displacement lobe rotor type pumps. As the rotor rotates, the volume in the pump inlet line increases and the fluid is dragged into the pump. The fluid between the rotors and the pump inner wall is conveyed to the pump outlet. The fluid is transferred to the outlet line as a result of the reduction in volume at the outlet with the rotation of the rotor.

Options

-

Heating Jacket for the Pump cover

-

Single / Double Mechanical Seal according to the application

-

Vertical entry and exit

-

Single Wing, Bi-Wing, Tri Lobe, Multi Lobe options

-

Safety Valve (By-Pass) can be mounted on the pump cover

-

Input and output norms are DIN 11851 as standard. It can be made with Tri Clamp or DIN flange on request.

Features

-

EHEDG and 3A standards and certificates

-

4 different rotor types (Single Wing, Bi-Wing, Tri Lobe and Multi Lobe). All rotor types are interchangeable without any clearance changes.

-

Thanks to their positive displacement feature, they are used in the transfer of low, medium and high viscosity fluids without any problems.

-

Easy assembly and maintenance

-

Front-loading packing perfectly designed for hygienic applications.

-

A single mechanical seal pump can be converted to a double (flush) mechanical seal with minimal parts requirement.

-

The pump, which is supplied as a side inlet / outlet as standard, can easily be converted to top inlet / bottom outlet.

-

Ability to rotate in both directions (Clock hand and counterclockwise)

-

Since the material quality of the surfaces in contact with the fluid is AISI 316 stainless steel, they are used in applications requiring hygiene.

-

Thanks to the rotor type specially designed for the transfer of granular / particulate fluids, the product is not damaged during the transfer.

Performance

|

Model |

Input / Output Size |

Capacity |

Max. Revolution (RPM) |

Max. Differential Pressure | |||

| mm | inch | Lt/1 Rev. | GPM |

PSI |

BAR |

||

|

PL 115 |

15 |

½'' |

0.02 |

0.53 |

1000 |

290 |

20 |

|

PL 125 |

25 |

one" |

0.05 |

1.32 |

|

|

|

|

PL 140 |

40 |

1 ½'' |

0.12 |

3.17 |

800 |

175 |

12 |

|

PL 150 |

50 |

2" |

0.21 |

5.54 |

|

115 |

8 |

|

PL 250 |

50 |

2" |

0.4 |

10.81 |

700 |

175 |

12 |

|

PL 265 |

65 |

2 ½'' |

0.62 |

16.35 |

|

115 |

8 |

|

PL 380 |

80 |

3” |

1.02 |

26.9 |

600 |

175 |

12 |

|

PL 3100 |

100 |

4” |

1.44 |

37.98 |

|

115 |

8 |

|

PL 4100 |

100 |

4” |

2.27 |

59.88 |

500 |

175 |

12 |

|

PL 4125 |

125 |

5” |

3.34 |

88.1 |

|

115 |

8 |