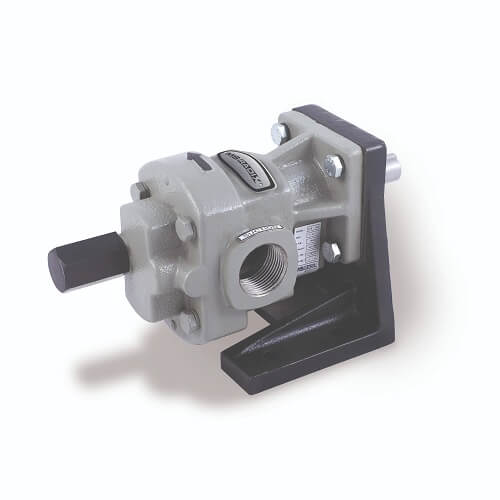

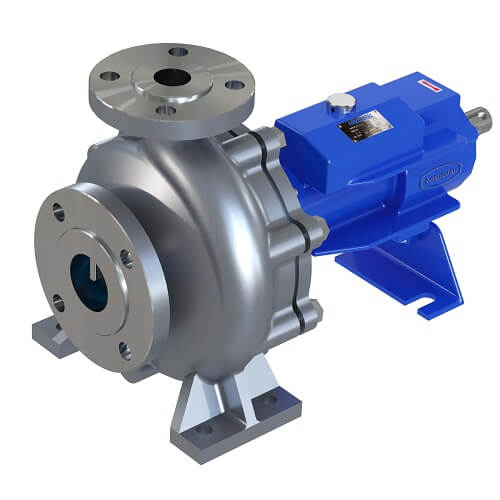

MSX Series Rotary Gear Pump

MSRADIX® MSX Series Rotary Gear Pumps are the most efficient and economic range of flange and foot mounting type positive displacement rotary gear pump. MSX series pumps have a single helical shrink fitted gear pair and hardened and grind finished shaft. Ultra bronze sintered bushes ensured smooth running. It is perfectly designed and constructed, which increases the life and performance of the pump. These pumps are similar to the MS type in construction. MSX monoblock version is available in simple and compact design and it is not required to align every time when coupled with Electric Motor.

MSX series pumps are foot mounted with ‘L’ Bracket or Flange mounted

Suction size from ½” to 3” BSP.

Capacity: 20 LPM to 350 LPM.

Maximum working pressure: 12 Bar.

Maximum working temperature: 80oC for standard & 200oC for MSX (HT).

Maximum viscosity: 100000 SSU.

Sealing options: oil seal / gland packing / single mechanical seal.

Sturdy design and construction to ensure long trouble free life with best performance.

Pressure relief valve will be provided in all models.

All general purpose viscous fluid like lube oil, paints, transformer oil, LDO.

MSX pumps can handle following liquids –

All kind of mineral oils.

All kind of vegetable oils.

Coal tar, bitumen, asphalts.

Paints and varnish.

Sugar molasses & syrups.

All kinds of fish and animal oils.

Glycerin & glycol.

Fuel oil, diesel oil & furnace oil.

Soap solution & lard.

Glue.

Viscous chemicals.

Model & Performance Chart

Pump Model | Suction & Delivery | Capacity at 1440RPM | Recommended Motor BHP at differential pressure (kg/cm2) with 1500SSU Viscosity | ||||||||||||

LPM | US GPM | m3/hr | Kg/cm2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

MSX-050 | ½” x ½” | 20 | 5.28 | 1.2 | KW | 0.30 | 0.35 | 0.40 | 0.45 | 0.50 | 0.55 | 0.60 | 0.65 | 0.70 | 0.75 |

HP | 0.50 | 0.75 | 1.00 | ||||||||||||

MSX-075 | ¾” x ¾” | 30 | 7.92 | 1.8 | KW | 0.37 | 0.45 | 0.54 | 0.62 | 0.69 | 0.77 | 0.85 | 0.92 | 1.01 | 1.09 |

HP | 0.75 | 1.00 | 1.50 | ||||||||||||

MSX-100 | 1” x 1” | 50 | 13.20 | 3.0 | KW | 0.40 | 0.50 | 0.60 | 0.75 | 0.89 | 1.04 | 1.17 | 1.30 | 1.44 | 1.59 |

HP | 1.00 | 1.50 | 2.00 | ||||||||||||

MSX-125 | 1¼” x 1¼” | 75 | 19.81 | 4.5 | KW | 0.70 | 1.00 | 1.20 | 1.40 | 1.50 | 1.90 | 1.95 | 2.5 | 2.35 | 2.55 |

HP | 1.50 | 2.00 | 3.00 | ||||||||||||

MSX-150 | 1½” x 1½” | 110 | 29.05 | 6.6 | KW | 1.05 | 1.45 | 1.95 | 2.10 | 2.40 | 2.65 | 2.95 | 3.25 | 3.60 | 3.75 |

HP | 2.00 | 3.00 | 5.00 | ||||||||||||

MSX-200 | 2” x 2” | 225 | 59.44 | 13.5 | KW | 2.00 | 2.50 | 3.20 | 3.70 | 4.30 | 4.55 | 5.60 | 6.20 | 6.90 | 7.11 |

HP | 3.00 | 5.00 | 7.50 | ||||||||||||

MSX-250 | 2½” x 2½” | 350 | 92.46 | 21.0 | KW | 4.15 | 5.20 | 6.10 | 7.30 | 8.20 | 9.10 | 10.30 | 11.20 | 12.10 | 12.25 |

HP | 5.00 | 10.00 | 12.50 | ||||||||||||

Material of Construction

| Parts | MSX up to 80oC | MSX (HT) up to 200oC |

| Body | IS:210 FG 220 C.I. Grade | IS:210 FG 220 C.I. Grade |

| Back Cover | IS:210 FG 220 C.I. Grade | IS:210 FG 220 C.I. Grade |

| Gears | EN-8 | EN-353 Nitrided |

| Shaft | EN-19 H.G. | EN-19 H.G. |

| Bushes | Non-Ferrous | Non-Ferrous |

| Seal | Neoprene Oil Seal | Gland Packing |