Centrifugally Cast

Centrifugal casting, also known as centrifugally cast, is a casting technique used to create cylindrical-shaped objects with a high degree of accuracy and structural integrity. It involves rotating a mold at high speeds while pouring molten metal into it.

AUTOMOBILE LINERS AND SLEEVES

REFRIGERATION ENGINE LINERS

HEAVY EARTHMOVER LINERS

SPECIAL PURPOSE LINERS

· All liners are made of Centrifugal

Casting and Shell Casting which gives Homogeneous structure and uniform

hardness.

· Free from casting defects like blow

holes, porosity and cracks.

· Highly qualified and dedicated

workforce to achieve zero defect components.

· Quick and in-time delivery due to

in-house hi-tech manufacturing facility.

PRODUCT RANGE

Cylinder Liners, Dry Sleeves & Air /

Water Cooled Blocks (On Road & Off Road Engines)

|

Segment |

Application |

|

Automobile

|

Cars:

Hatchback, MUV/SUV, Sedan, Racing Cars (SG Iron)

(Toyota,

Mitsubishi, Maruti, Tata, Ford, Honda etc.) |

|

Commercial:

Heavy Commercial / Light Commercial (TATA, Leyland,

Hino, Man, Mercedes, Fiat etc.) |

|

|

Tractors:

(Eicher, Urasa,

Sonalika, John Deere, Perkin, Massy etc.) |

|

|

Earthmovers

|

Heavy

Earthmovers, Light Earthmovers, Lawnmovers (Caterpillar,

JCB, Komatsu, Kubota etc.) |

|

Generators

|

Power Generators

(Cummins,

Caterpillar, Perkins, Mahindra etc.) |

|

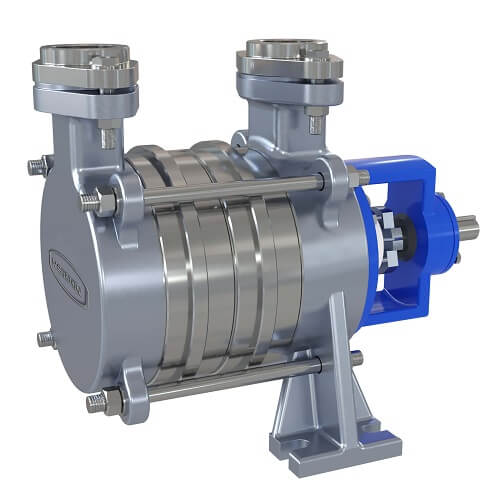

HVAC

|

Reciprocating

Ammonia Compressor, Freon Compressor (Grasso/Sabro/Mycom/Vilter/York/Carrier/Gram

etc) |

|

Air/Water

Cooled

Blocks

|

Deutz, Lister,

Kirloskar, Greaves, Tatra etc. |

|

Compressor

|

Air & Gas

Compressor – as per customer specifications |

|

Pneumatics

|

As per customer

specifications |

|

Marine

|

As per customer

specifications (Cast Iron, Ni – resist) |

|

Mining

|

As per customer

specifications (MTU, Cummins,

Caterpillar, Arrow, Komatsu etc.) |

|

Locomotive

|

Railway Engine

Liner & Parts |

|

Defence

|

Parts of DRDO &

Ammunition Factory (Steel Liner) |

We also develop any type of cylinder

liners as per customer drawing / sample &

specifications.

TECHNICAL

SPECIFICATIONS

|

Description |

Details |

|

Metal |

Cast Iron, SG

Iron, Steel, Ni-resist |

|

Inner Diameter

|

45 mm – 400 mm

|

|

Outer Diameter

|

50 mm – 500 mm

|

|

Length |

Upto 650 mm |

CHEMICAL COMPOSITION OF GG 25

GRADE

|

LIMIT

|

C

|

Si

|

S

|

Mn

|

Ni

|

Cr

|

Mo

|

Cu

|

P

|

|

MIN. |

3.00 |

1.60 |

- |

0.3 |

0.005 |

0.006 |

- |

- |

- |

|

MAX. |

3.70 |

2.70 |

0.15 |

1.0 |

0.5 |

0.4 |

0.5 |

0.5 |

0.35 |

DIMENSION OF GG 25

GRADE

|

PRODUCT

|

PARAMETERS

|

TOLERANCE

|

|

|

Finished

Centrifugally Cast Cylinder Sleeves |

Length |

± 0.2

mm

|

|

|

I.D. |

F.F. |

- 0.025 mm |

|

|

S.F.

|

± 0.1

mm

|

||

|

Outer Diameter

|

±

0.025mm

|

||

|

Collar Diameter

|

±

0.025mm

|

||

|

Collar Width

|

± 0.05mm

(finished)

± 0.1mm

(semi-finished)

|

||

Hardness: 190-260 BHN

Tensile Strength:

22-25 Kgf/sqm

Surface

Roughness: 0.4 to 0.8 micron

Micro Structure:

Graphite Type: “A” & “B” (“D” & “E”

random)

Flake Size: Max. 4 – 8

Matrix: Free Ferrites max 5-6%